Satoen’s unique integrated production system

Satoen works to maintain and enhance the reliable quality of our products-from cultivation to manufacturing and product development-and aims to deliver products that ensure complete customer satisfaction.

-

01CULTIVATION

Tea Fields

Tea Fields -

02MANUFACTURING

Factories

Factories -

03FOOD SAFETY

STRATEGY Research Laboratories

Research Laboratories -

04PRODUCT

DEVELOPMENT Products

Products

Our integrated production system

ensures reliablequality and safety control

01CULTIVATION

A unique agricultural systemthat enlists experts in soil, cultivation and harvesting

Cultivation experts check each of our tea fields regularly to ensure that all tea leaves meet Satoen quality standards. In this unique agricultural system, experts lead the cultivation process with our research laboratories.

CERTIFICATIONS

- ◎In Japan:

- Organic JAS, HALAL, Kosher, FSSC22000 (ISO 22000)

(Sato Tea Production Co., Ltd. has obtained FSSC22000, Organic JAS, HALAL and Kosher certification)

- ◎In Vietnam:

- HALAL and ASIAGAP

Agricultural Production Corporation SEIRYU-KAI Co., Ltd.

Maintains tea fields data (owner’s name, field area, variety)and manages fertilization and cultivation.

Agricultural Production Corporation Seiryu-kai Co., Ltd. manages our tea fields. They analyze the soil at the Satoen Food and Drug Laboratories and grow the leaves that will become tea. They determine appropriate fertilization to suit the land, raise the tea leaves with painstaking care, and then pick them during the best possible harvest period. Careful time management ensures that all of the collected leaves arrive at the factory within two hours.

02MANUFACTURING

Providing high-quality tea

at reasonable prices

CRUDE TEA

Potential output of approx.

10,000kg / day

We process our leaves immediately after harvesting them, and our products have earned customers’ trust thanks to the thoroughness of our quality preservation measures and processing inspections. With integrated production that cuts out the middlemen, our unique system allows us to offer high-quality tea at reasonable prices.

FINISHING

Approx.

5,000kg / day

We sort the tea leaves selected at our strictly hygiene-controlled factories and carefully inspect them for firing, aroma and appearance, etc., on our integrated production line. With controlled temperature, humidity and air pressure levels, the factory clean room where we produce our high-quality tea looks completely different from how you might imagine conventional tea factories.

*Air pressure is controlled within the clean room, preventing outside air or foreign objects from entering.

PACKAGING

tea packs for retail sale

Approx.

24,000packs / day

tea bags

Approx.

20,000teabags / day

A wide variety of teas can be manufactured here,

ranging from sencha to extract powder

-

SENCHA

SENCHA -

HOJICHA

HOJICHA -

BLACK TEA

BLACK TEA -

MATCHA

MATCHA -

GRANULATED

GRANULATED

POWDER -

CTC

CTC

GREEN TEA -

EXTRACT

EXTRACT

POWDER -

TENCHA

TENCHA

03FOOD SAFETY

STRATEGY

STRATEGY

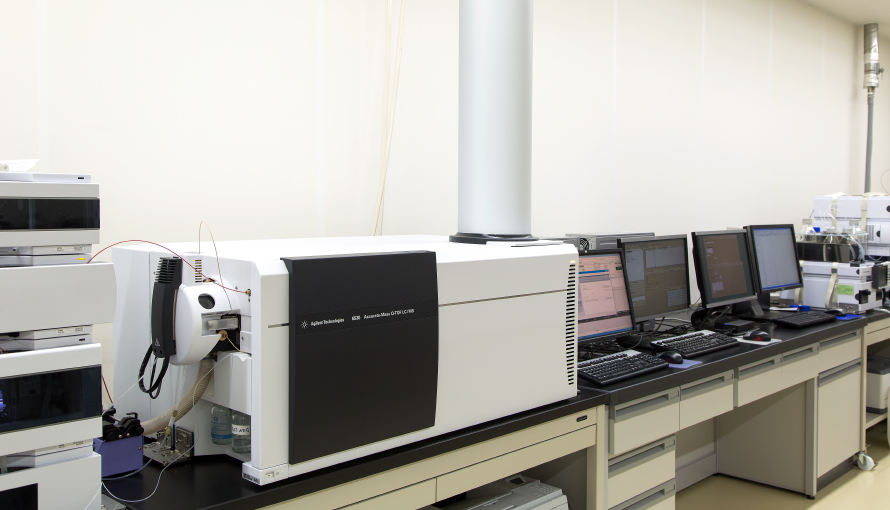

SATOEN

Food and Drug Laboratories

A thorough system for ensuring quality from product development

and production to manufacturing and sale

and production to manufacturing and sale

We utilize state-of-the-art-equipment for agricultural chemicals inspections and radiation testing, etc., to check that we meet our own strict standards.

Agricultural chemical management

and radiation testing

and radiation testing

For agricultural chemical management, we conduct simultaneous analysis screenings for 200–300 types of residual pesticides. And in addition to testing for radiation, we can also conduct separate analysis for individual pesticide components at the customer’s request. Satoen remains the only company capable of such thorough

in-house analysis.

Each lot is analyzed for radiation and residual pesticides

04PRODUCT

DEVELOPMENT

DEVELOPMENT

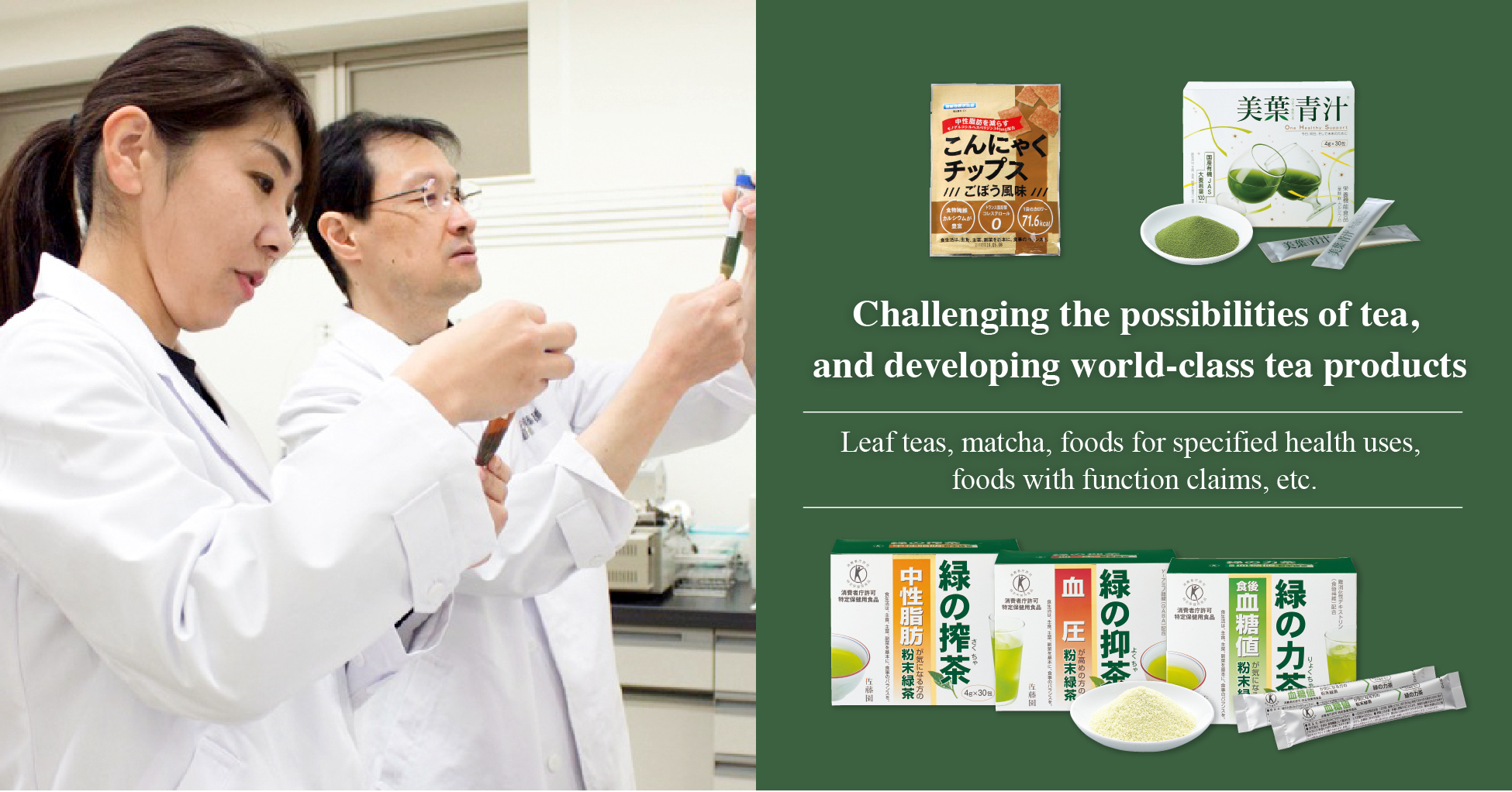

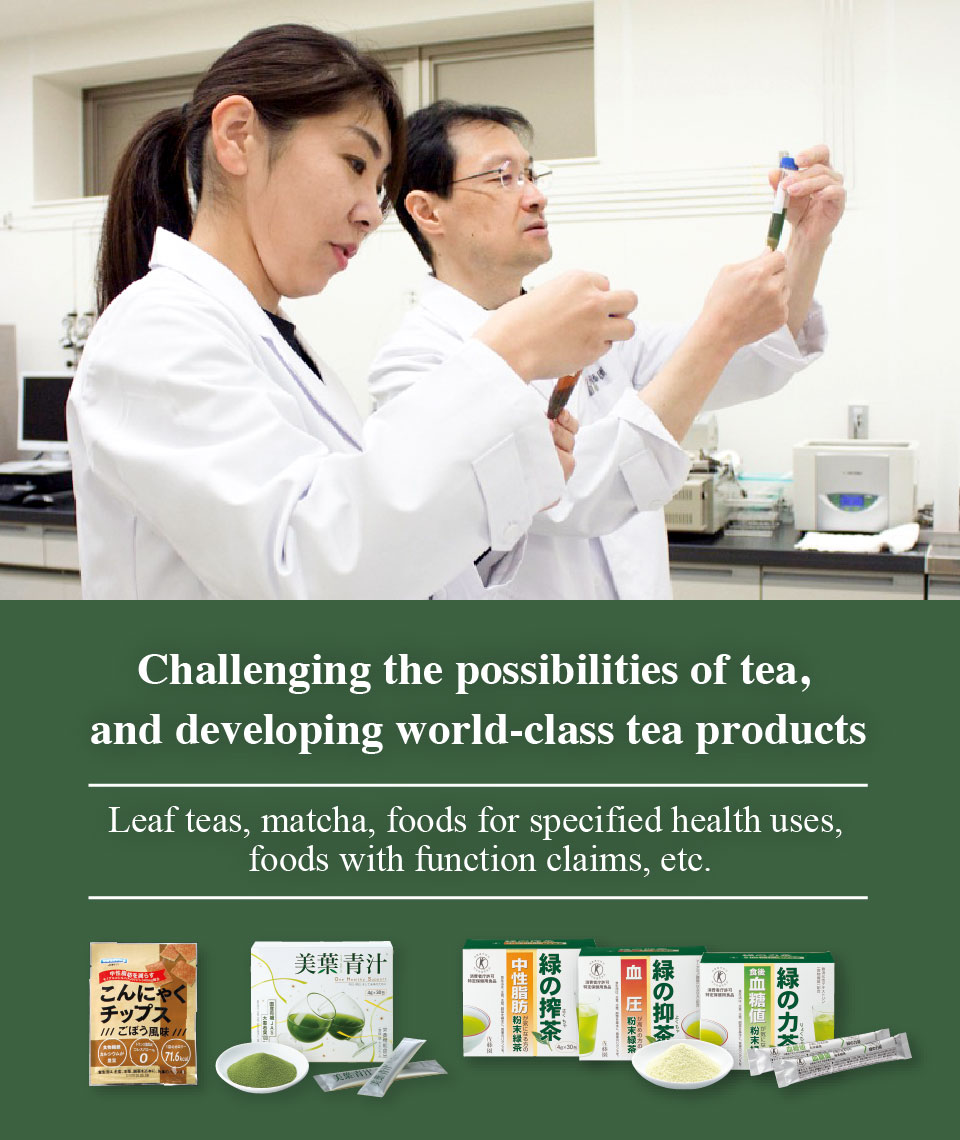

Challenging the potential of tea

and developing world-class products

Not limited to the role of tea manufacturer, Satoen is also working on plans and projects to draw out the potential of tea and bring new products to market.

Partnerships with universities and research institutions

We are developing products backed up by data and clinical evidence in collaboration with universities and research institutions. Exploring botanical components—with a focus on tea—from around the world, we continue to investigate their effects and efficacy as well as their potential in various fields.

New component quantification is also possible

In order to deliver reliable products to consumers, all products brought to market must pass inspection and meet our rigorous in-house standards.

Product development examples

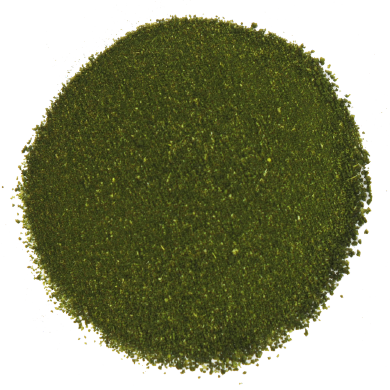

Matcha

The assured guarantee of Satoen quality

- - Product example: Matcha latte

- - Domestic shipment volume: approx. 30t

- - Annual export volume: approx. 10t

Agricultural chemical analysis is carried out on each lot.

We quantify color differences and particle sizes.

Disinfection can also be conducted.

We quantify color differences and particle sizes.

Disinfection can also be conducted.

Foods for specified health uses / foods with function claims

Reliable evidence

We have a solid record of developing foods

for specified health uses

We have a solid record of developing foods

for specified health uses

- - Product examples: Green Sakucha / Green Yokucha / Green Ryokucha1

- - Classification: Foods for specified health uses

- - Product examples: Konnyaku chips (burdock root flavor)2

- - Classification: Products with function claims

We also accept requests from and collaborate with major food and pharmaceutical manufacturers based on our extensive experience as a comprehensive tea manufacturer.

Other health food products

Various dosage forms and signature formulas

- - Product example: Biyo Aojiru1

- - Form: powder

- - Product example: Tsuya-bijin

- - Form: jelly

Toiletry products

Developing high-quality products

featuring unique ingredients

featuring unique ingredients

- - Product example: Ocha-gokoro Catechin Green Tea Tooth Paste1

- - Product example: Salala Handcream2

- - Product example: Chahoseki Green Tea Soap3

THE PRODUCT DEVELOPMENT PROCESS

-

1Contact

-

2Meeting

Concept sharing -

3Product planning

/ proposal -

4Selecting and developing

ingredients -

5Meeting

Adjustments

(inspection) -

6Final check

Contract / Order -

7Product

Registration -

8Transaction

/ Delivery

VIETNAM

FACTORY

FACTORY

From the tea fields of Vietnam

to the world

Our state-of-the-art production line in Vietnam,

a country that attracts buyers from around the world, helps meet

the global demand for sencha and matcha.

At Satoen in Vietnam, we are now able to manufacture high-quality Japanese tea and matcha outside Japan for the first time. We meet the worldwide demand for sencha and matcha from this production line equal to factories in Japan, and we operate advanced agriculture as the only such factory in southeast Asia.

Tea field area

100ha

Matcha (Tencha)

production line

production line

Approx.

2,500kg

Certifications

・HALAL

・ASIAGAP

・ASIAGAP

Sencha

production line

production line

Approx.

2,000kg

Please feel free to contact us.

■Business hours: 9 a.m. to 6 p.m. Mon. to Fri.

1057 Ohara, Aoi-ku, Shizuoka City, Shizuoka Prefecture 421-1392

Access

When coming by car

- Shin-Tomei Expressway

Shizuoka Service Area Smart Interchange (ETC Only) - – Inbound: 7 min. by car

- – Outbound: 9 min. by car

- Along National Route 362

When using public transportation

- Shizutetsu Bus / Warashina Line

- – For Ohara-mori (Route 134)

- – For Hachiman (Route 135)

- – For Kyuno (Route 136)

- – For Saka no Ue (Route 137)

- – For Hinata (138)

- – For Mizumiiro (Route 140)

1 min. walk from “Naka-warashina Gakko Iriguchi” bus stop

*Please be aware that only a limited number of buses

operate on these routes.

The Shizutetsu Bus timetable is available here >>

operate on these routes.